Exposure control devices, or ECDs, describes all ventilated engineering controls designed to protect the health of the user during lab and non-lab procedures and processes. ECDs protect users from a variety of hazardous materials:

- Hazardous vapors and gases (chemicals)

- Particulate matter (wet or dry) - dust, shavings, powders, and welding processes

- Heat

Below are examples of common ECDs found on UK campuses. ECDs can be designed to work specific for a lab, therefore, having a unique identification. The name is defined by it's opening type, exhaust purpose, and/or how it is positioned.

| ECD | Suitable for: | NOT Suitable for: |

| Most chemical and thermal manipulation operation. | Biological or material manipulation operation. | |

| Specific chemicals (contact OHS for approval of use) | Hazardous materials or large quantity of chemical manipulation. | |

| Chemical and thermal manipulation operation that utilize small quantities in a localized area. | Biological or material manipulation operation nor chemical and thermal manipulation operation that utilize larger quantities or a greater surface area than the hood itself. | |

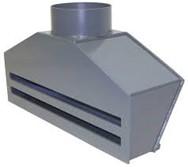

| Most thermal manipulation operation | Any chemical, biological, or material manipulation operation | |

| Material manipulation operation | Hazardous chemical or thermal manipulation operation | |

| Tissue dissections | Any other chemical process, thermal, or material manipulation operation | |

| Chemical manipulation operation in which the hazardous material weighs more than the density of air. | Any chemical manipulation operation where the hazardous material weighs less than the density of air. This ECD is also not suitable for biological, thermal, or material manipulation operation. | |

| Most chemical processes that require a specific atmospheric pressure. | Any thermal, biological, or material manipulation operation. Please note this ECD is considered a lab equipment, for it is not attached to the building's air system. The lab is responsible for the maintenance of this ECD. | |

| Biological manipulations depending upon the type of cabinet | Any chemical, thermal, or material manipulation operation. Please note this ECD is considered a lab equipment, for it is not attached to the building's air system. The lab is responsible for the maintenance of this ECD. | |

| Paint spraying manipulation operation | Any other chemical, biological, thermal, or material manipulation operation. | |

|

Barrel Filling Hood |

Liquid waste dumping processes | Any other chemical, biological, thermal, or material manipulation operation. |

| Physical manipulation operation with animal dandruff as the hazard source | Any chemical, biological, thermal, or material manipulation operation. Please note this ECD is considered a lab equipment, for it is not attached to the building's air system. The lab is responsible for the maintenance of this ECD. | |

| Non-infectious material manipulation (e.g., media preparation). This ECD provides a dust-free environment. | Any chemical, infectious biological, thermal, or material manipulation operation. Please note this ECD is typically considered a lab equipment for it is not attached to the building's air system. The lab is responsible for the maintenance of this ECD. |